Selecting the right pump for your dewatering requirements is crucial if you want to achieve efficiency, cost-effectiveness, and optimal performance. If looking at the different applications, like industrial, construction, and agricultural, the most widely used pumps are submersible and centrifugal pumps.

However, both are used to transport water, but they differ significantly in design, operation, and applications.

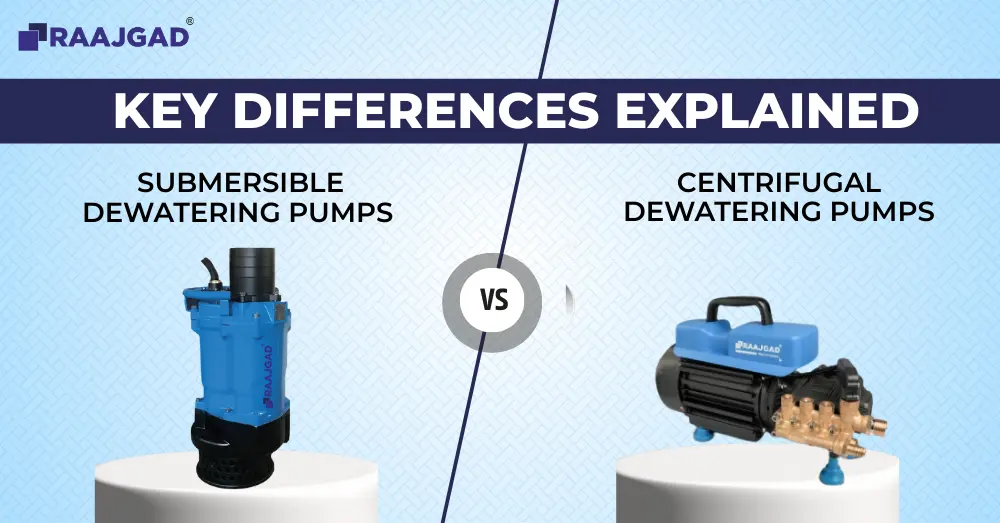

In this guide, we will compare the Submersible vs Centrifugal Dewatering Pumps or the main differences between centrifugal and submersible pumps so that you can make a better-informed decision for your next dewatering project.

Till the end of this blog, you will know exactly which pump is right for your requirements.

What are Submersible Pumps and Centrifugal Pumps

Submersible dewatering pumps are designed to operate while fully submerged in water. These pumps have a hermetically sealed motor and pump assembly.

These pumps force water to the surface by turning rotary energy from the motor into kinetic energy. Since they are submerged, they minimize problems like cavitation and maximize efficiency in high-water-level applications.

Contrary to submersible pumps, centrifugal pumps are installed above the water source. They use a rotating impeller to move water. These impellers transfer water through the pump and then out into the discharge point.

Centrifugal pumps pull water into the pump rather than pushing it from within the liquid.

Based on their unique capabilities, both pumps are extensively used in construction, mining, agriculture, municipal water supply industries, etc.

Quick Comparison Table

| Feature | Submersible Pump | Centrifugal Pump |

| Installation & Operation | A submersible pump is installed under the water and pushes water from within the liquid. | A centrifugal pump is installed above the water level and pulls water from a source via a suction pipe. |

| Efficiency | A submersible pump is more efficient for high-head/ deep applications. | As compared to submersible pumps, centrifugal pumps are less efficient for high-head applications. |

| Maintenance | It is difficult to access for maintenance as it is submerged. | Centrifugal pumps are easy to access and maintain. |

| Cost | These pumps generally have a higher upfront cost. | As compared to submersible pumps, centrifugal pumps have a lower upfront cost. |

| Applications | Submersible pumps are typically used in deep wells, dewatering, sewage treatment, and the mining industry. | Centrifugal pumps are typically used for water transfer, irrigation, chemical processing, and trash pumping. |

Key Differences Explained (Submersible vs Centrifugal Dewatering Pumps)

You have gained an understanding of the submersible pump and centrifugal pump, and a quick comparison of the Submersible vs Centrifugal Dewatering Pumps. Now, let’s understand the key differences between each in detail.

1. Design & Installation

Submersible pumps are designed to run underwater, featuring a sealed motor that does not allow water to enter. This enables them to thrust water from the point of origin directly without priming.

They are small and can be lowered directly into wells, sumps, or tanks.

Centrifugal pumps, on the other hand, are mounted over the water supply.

They are primed to remove air from the pump casing and avoid cavitation. Due to their open structure, they are easier to maintain but are not as suitable for applications in deep water.

2. Operating Principle

Submersible Pumps apply the motor and impeller in water directly to force liquid upward. This structure minimizes the possibilities of airlock and maximizes efficiency under high lifts.

Centrifugal Pumps use an impeller to generate a centrifugal force that sucks water into the pump and pushes it out.

It is more effective for shallow water or moderate lift, but not for suction at deeper depths.

3. Application Suitability

Before making any decision regarding the pump, you should consider its application and

Whether to use a submersible or centrifugal pump is greatly determined by your project needs:

Submersible Pumps: Suitable for deep wells, areas prone to flooding, and industrial dewatering. Best for applications where water levels are high and direct pumping from the source is necessary.

Centrifugal Pumps: Suitable for irrigation, drainage, and surface transfer of water. Ideal for average water depth and situations where above-ground installation is desired.

4. Efficiency & Energy Usage

Submersible pumps are preferable for transferring water from deeper sources since they push water and not pull. This minimizes energy loss through suction restrictions. Moreover, submergence lowers noise levels and prevents cavitation.

Centrifugal pumps are efficient for shallow water uses. But when operated beyond the optimal suction depth, they will need higher power to sustain performance, raising the cost of operation.

5. Maintenance & Lifespan

Submersible Pumps need regular checks of wear, seal condition, and motor health. As they are submerged in water, maintenance can include removing the pump from the water for a short period.

As compared to the submersible pumps, centrifugal pumps are simpler to check and service as they are mounted above ground. However, regular priming and lubrication are essential to maintain consistent performance.

On the matter of longevity, both pumps are long-lasting when well taken care of, but submersible pumps last longer in high water conditions because there is less motor stress.

6. Cost

Cost is also a very important factor when choosing between the submersible pump and the centrifugal pump.

Submersible pumps typically carry a higher cost because of the sealed motor design and heavy-duty construction.

Centrifugal pumps are usually less expensive, which makes them perfect for projects with limited initial investment.

It is also important to note that efficiency, energy conservation, and lower maintenance in the long run, makes submersible pumps a cost-effective choice for heavy-duty applications.

Why choose Raajgad for your next Pump purchase?

In choosing a pump, reliability, efficiency, and support matter most. Raajgad Techno has a variety of submersible and centrifugal pumps that are built to meet the highest industry standards. Let’s have a look at how choosing the Raajgad pumps can change your experience.

1. Quality & Longevity: Raajgad Pumps are built with the finest materials to provide great performance.

2. Extensive Range: Whether you need the dewatering pump for construction or irrigation, the extensive range of Raajgad Pumps ensures you have a solution for every unique need.

3. Technical Support: Our 24/7 technical support from experts enables you to select the best pump for site-specific conditions.

4. After-Sales Service: Our job doesn’t end at providing the pump. Apart from providing a pump, we also ensure regular maintenance and spare part service guarantee for an uninterrupted operation.

In short, selecting Raajgad is like investing in a pump that will provide uniform performance, less downtime, and high productivity.

Knowing the difference between centrifugal pumps and submersible pumps is critical in the selection of proper equipment for your application.

Centrifugal pumps are best suited for shallow water and surface work, while submersible pumps are best for deep-water and high-head applications.

By considering other factors such as installation, efficiency, maintenance, and cost, you can make a well-informed decision that best meets your project requirements.

Whether you need an industrial, agricultural, or construction-specific requirement, Raajgad Pump always has the appropriate pump to provide smooth operations and enduring results.