Have you ever wondered what goes into a successful construction or mining project?

It’s not just strong foundations, skilled site workers, and high-end machinery, but also a smooth dewatering process that helps in maintaining a dry, safe, and ready-for-progress environment. Without it, the ground under these projects becomes weak and unsafe.

That’s why dewatering is like a silent helper that engineers depend on to keep everything strong and stable.

In this blog, we’ll understand how a dewatering process works, what its benefits, challenges and what commonly used techniques are.

What is Dewatering?

In simple terms, dewatering is the process of removing water from a location. This process is mainly applied in construction or industrial sites.

How Does the Dewatering Process Work?

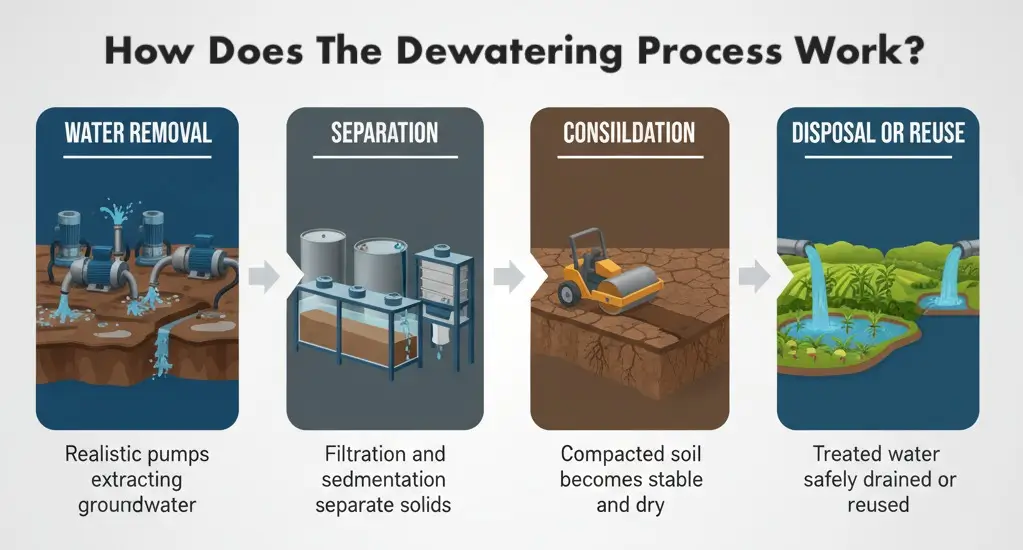

Dewatering is a simple yet complicated process that requires seriousness, technique, expertise, and complete knowledge. The dewatering process moves through several key steps that ensure a smooth dewatering operation.

Let’s understand this process in detail:

1. Water Removal

The very first step involves removing standing or collected water. Dewatering is done with the help of pumps, such as submersible dewatering pumps, wellpoint systems, or sump pumps. It depends on the location, soil type, and depth of the groundwater, that which pumping system will be used.

Raajgad Pump Services provides high-quality and affordable dewatering pumps, that remove water efficiently in no time. From our wide range of dewatering pumps, you are free to select those that fulfill your requirements perfectly.

2. Separation

After the collection of water, there are chances that it may contain hard solids, sediments or small particles. It is important to separate these solids to make the water usable or safely disposable. This separation can be done through filtration or sedimentation.

3. Consolidation

After excess water is removed, the remaining solid begins to settle and compact. This increases its strength and stability. This stage is called consolidation, where the structure built on the site remains secure and long-lasting.

4. Disposal or Reuse

The last and final stage involves managing the extracted water. It depends on the quality of water that whether it will be reused or disposed of. However, such waters can be used for irrigation, dust control, or other industrial purposes.

Common Dewatering Techniques

Every construction site is different, that’s why dewatering process requires different techniques and methods. Let’s explore commonly used dewatering techniques, so that you choose the right technique that works well for your project.

1. Wellpoint system:

The Wellpoint system is a combination of small wells connected to a vacuum pump that helps to remove water from shallow depths. This system is highly effective for sandy soils.

2. Deep Well System:

Deep well dewatering is mostly used for projects that require high-capacity pumping. This system depends on large wells equipped with submersible pumps that remove water from greater depths.

3. Sump Pumping:

Sump pumping is commonly used for small dewatering requirements. Here, water is collected in sumps or pits and then pumped out using submersible pumps. It is one of the cost-effective techniques for dewatering. However, it is less effective when used for large-scale operations.

4. Eductor System:

This method uses high-pressure water to create a vacuum, drawing groundwater out through eductors. It works well in soils with low permeability (the soil’s ability to allow fluids, such as water, to pass through its interconnected pores).

Benefits of Dewatering

Dewatering comes with various benefits like improved safety, reduced time and labor, and other environmental benefits. Here’s a brief explanation of dewatering benefits:

- Improves Safety: One of the biggest benefits of owning a dewatering system for your project is that it helps to keep excavation areas dry. This reduces the risk of accidents or equipment damage.

- Quick Project Progress: Traditional dewatering methods, like using a hose and bucket, were time-consuming and required a whole lot of labor and effort. Today, dewatering through suction pumps has made things easy, saving time and manpower as well.

- Prevents Soil Erosion: Another major benefit of the dewatering process is it controls groundwater pressure, ensuring soil stability.

- Environmental Protection: Since dewatering prevents waterlogging, erosion, and contamination, this helps to keep the nearby environment and its people safe, eventually eliminating the risk of lives that can be lost through waterlogging.

Applications of the Dewatering Process

Dewatering can be done through various techniques, like deep well systems, sump pumping, etc. Such techniques of the dewatering process can be used in various applications like construction, mining, infrastructure development, and more.

Let’s explore different applications where the dewatering process can be used as an effective method for water removal:

- Construction Projects: This includes projects like basements, tunnels, bridges, and road foundations.

- Mining Operations: To remove water from mining pits and tunnels.

- Infrastructure Development: This includes removing water from public places like roads, bridges, and tunnel construction areas to keep the work zones dry.

- Wastewater Treatment: To separate water from sludge and reduce waste volume.

- Flood Management: In case of a flood, the dewatering process helps to drain excess water from low-lying or flooded areas.

Challenges in Dewatering

The dewatering process comes with its own set of challenges like soil differences, environmental regulations, and more.

Let’s understand these problems in detail, so that you can be prepared and take the required action according to your project conditions.

- Soil Conditions: Low-permeability soils like clay prevent water flow and make pumping less efficient.

- Environmental Regulations: In areas with strict discharge regulations, you can’t dispose of water at any random place. Hence, before proceeding with dewatering, gain a deep understanding of the environmental regulations in that particular area or place.

- Equipment Maintenance: Dewatering is done with the help of pumps and other tools. With continuous operation in harsh environments, this equipment may lead to wear and tear. Hence, they require proper and constant service.

- Unpredictable Water Inflows: Heavy rainfalls can mismanage water levels, which can affect the dewatering pump efficiency.

Raajgad Pump: Leading the Way in Dewatering Solutions

With over 24 years of industry experience, Raajgad Pump has successfully served in 1000+ projects. At Raajgad Pump, we provide complete dewatering solutions to meet the demands of construction, excavation, and infrastructure projects.

If you are looking for a cost-effective and reliable dewatering solution for your construction site in Pune or across India, then the one by Raajgad Pump is an ideal choice for you.

Read alos: What is Dewatering System: Types, Working & Usage