Imagine building a house on a land full of water, where every step you take sinks into mud, and water keeps filling up the area.

Could you even imagine?

Ofcourse not because building any project in such places is impossible. That’s where dewatering in construction comes to the rescue.

Dewatering removes excess and unwanted water from sites. It maintains a safe environment by keeping the ground dry and stable. From low-water-level basements to bridges near the river, dewatering works wonders and provides a solid base for construction.

In this blog, we’ll read about various Construction Dewatering Methods, their advantages, and limitations.

Importance of Dewatering for Construction Projects

Dewatering is not just about removing water – it provides multiple other benefits that makes it an important part of construction projects.

Apart from maintaining a dry environment, here are some benefits of dewatering in construction:

- Dewatering improves soil strength and stability.

- It prevents flooding and water-related damage, protecting material quality and equipment.

- Dewatering ensures worker safety by removing water from high-risk areas like deep excavations.

Common Dewatering Methods

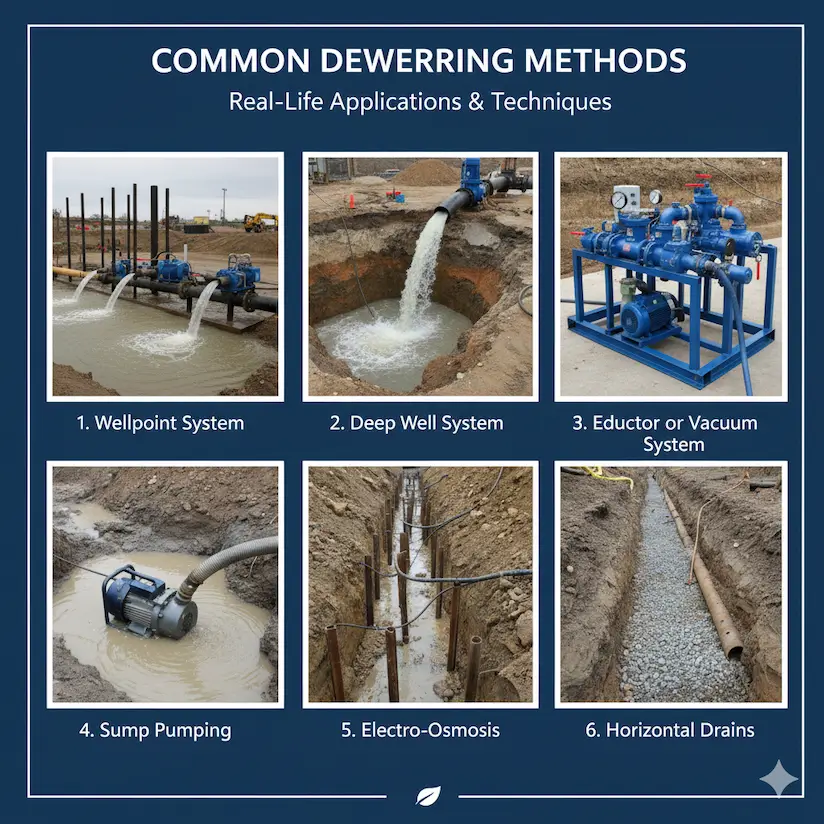

Dewatering is not limited to just one method. It includes various methods like the wellpoint system, the deep well system, the eductor system, sump pumping, and electro-osmosis.

Every construction dewatering system is designed for different needs and site requirements. Therefore, here’s a brief explanation of the different types of dewatering methods, so that you can choose the right method according to your project demands.

- Wellpoint System

One of the most common Construction Dewatering Methods is Wellpoint Systems. In Wellpoint, wells are fixed around the excavation area while being connected to a header pipe. The header pipe is further joined with a vacuum pump, which removes the groundwater.

- Deep Well System

In deep excavation areas, a deep well system is best suited for dewatering in construction. In this method, large wells are installed with submersible pumps and remove water through suction.

Raajgad Pump provides reliable, high-quality submersible pumps, suitable for higher volumes of groundwater.

- Eductor or Vacuum System

Here, educator wells are installed, which connect to two parallel headers. This system uses high-pressure water and vacuum to withdraw groundwater. Such dewatering methods are suitable for tight spaces and fine soil conditions.

- Sump Pumping

Another common and economical Construction Dewatering Methods is sump pumping. This method allows the groundwater to seep into the excavation area, and then, through the use of a pump, it draws water with the help of eductors.

- Electro-Osmosis

Electro-osmosis is not a usual dewatering techniques in construction as it is applied to sensitive sites. Here, water is moved through soil with the help of an electric current, making it effective for fine-grained soils.

How to Choose the Right Dewatering Method

Dewatering is a crucial part of any construction site; it has the ability to smoothly operate construction projects, but it can also turn into a mess if the wrong techniques or methods are used. Hence, it is important to choose the right dewatering method that suits your project.

Here are the key aspects that you should keep in mind while choosing the right dewatering method:

- First things first, understand the soil type and ground conditions.

- Look for the depth of excavation areas.

- Inspect water volume, as large volumes require higher capacity pumps.

- Ensure environmental regulations and the safety of the nearby areas and it’s people.

Advantages and Limitations of Each Method

Every construction site is unique and different in nature, requiring particular dewatering techniques in construction. Therefore, it is important to understand all types of dewatering methods, their advantages, and limitations as well.

Let’s understand the advantages and limitations of different dewatering techniques in construction.

| METHOD | ADVANTAGES | LIMITATIONS |

| Wellpoint System | This method works best for shallow excavations. Also, it is easy to set up and cost-effective. | Ineffective for deep, large sites and silty soils. |

| Deepwell System | Effective and handles large and deep sites very well. | This method is costly and complex in nature. And can even lower the water table. |

| Eductor / Vacuum System | Best for fine-grained soils and has precise control. | This method requires high energy and specialized equipment. |

| Sump Pumping | Simple, less technical, and fast for minor inflow. | This method is not suitable for heavy inflow or deep water tables. |

| Electro-Osmosis | Suitable for sensitive areas or fine soils. | The process is relatively slow compared to other dewatering methods. |

Innovations and Technology in Dewatering

From traditional dewatering methods to innovations of submersible and centrifugal pumps, dewatering methods have really evolved over time. Recent advancements have really improved the dewatering operations, making it easier for residents, farmers, contractors, and more. With improved technology and the development of newly designed construction dewatering pump, it has reduced time, labor, and effort.

In addition, these improved methods lead to more environmentally safe discharge of water, resulting in a safe and secure environment.

Dewatering is a necessity for construction, excavation, and mining operations. It provides a dry and safe environment, protecting both workers and machinery on the site.

If you’re planning a project that requires dewatering, it is important to use the right method, techniques, and equipment. Raajgad Pump provides high-performance, cost-effective, and reliable dewatering pumps, available in many variations and designs that ensure a smooth dewatering operation for your project.

For more information, visit https://www.raajgadpump.com/ and find the right dewatering method for your project.

FAQs

What is dewatering in construction?

The process of removing groundwater or surface water from construction sites is known as dewatering in construction.

Why is dewatering important for construction projects?

Dewatering helps to maintain a dry, safe, and secure environment which saves time, labor and also prevents structural damage.

What are the common methods of dewatering in construction?

Commonly used dewatering methods include wellpoint systems, deepwell systems, eductor/vacuum systems, sump pumping, and bypass dewatering.

How do I choose the right dewatering method for my site?

Consider site and environmental conditions, water table levels, size, and project requirements.

Are there environmental regulations to consider during dewatering?

Yes, local environmental regulations include discharging water in the suggested place and taking precautions before releasing water to prevent any kind of mismanagement and pollution.

What are the benefits of using wellpoint dewatering systems?

Yes, there are many benefits of well point dewatering, which include easy setup, being ideal for shallow excavations, and being cost-effective.