Key Summary: What is a Well Point Dewatering System ?

- Purpose – Removes groundwater to keep construction/excavation sites dry and stable.

- Working – Uses shallow wells (well points) connected to header pipes and a vacuum pump to extract and discharge water.

- Components – Well points, header pipes, pumps, discharge pipes, and accessories (valves, gauges, filters).

- Benefits – Cost-effective, efficient, flexible, minimal disturbance, and safer soil conditions.

- Limitations – Best for shallow depths (5–7 m), works mainly in sandy soils, and requires regular monitoring.

In India, water management goes beyond a simple task.

With uneven rainfalls and rapid industrialization, maintaining a dry environment requires careful planning and expertise, especially on a construction site. For such matters, well point dewatering offers a quick and efficient solution to ensure your project runs smoothly without any interruptions.

Through this blog, you’ll understand what is a well point dewatering system, how it works, what the necessary components are, and what its advantages and limitations are.

How does a well point dewatering system work?

You might wonder how a well point dewatering system actually works and what the process involves. Here’s an easy way to understand it.

Well point dewatering is a process of removing groundwater from a particular area.

The procedure begins with the use of small-diameter and shallow wells spaced throughout the area. These well points are interconnected to a riser pipe, which is again connected to a main pipe called the Header Pipe. Being linked to header pipes, the pump creates suction and draws water from the ground. The process ends by discharging the water through pipes into a safe space.

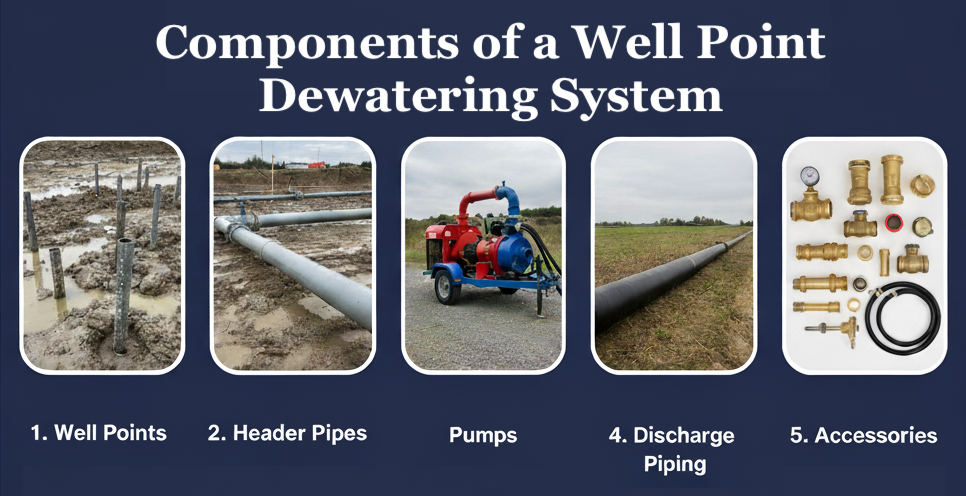

Components of a Well Point Dewatering System

Well point dewatering requires several important components that work as a team and provide a dry construction site. Components like well points, header pipes, and vacuum pumps are essential for the smooth functioning of your project.

Let’s understand why these components hold importance and how they work.

- Well Points:

Well points are basically perforated pipes made of PVC or steel, inserted into the ground for the collection of groundwater. These small pipes allow the water to flow into the dewatering system.

- Header Pipes:

Header pipes are large pipes laid horizontally on the surface. Connected to the pump through a flexible hose, header pipes link multiple risers and collect water from well points.

- Pumps:

Vacuum pumps are the main processing centre of the whole system. Typically located in a sump or tank, these pumps create suction and pull out water from the underground.

At Raajgad Pump, we provide all kinds of dewatering pump solutions according to your project’s size and requirements.

- Discharge Piping:

After the collection of underground water, discharge pipes carry the removed water and discharge it away from the site to a drainage channel, sewer, or safe location.

- Accessories:

During the whole well point dewatering process, other important components like Valves, filters, clamps, and pressure gauges ensure smooth operation and monitoring.

Applications and Benefits

Well point dewatering is a very beneficial and widely used process in different sectors of construction and civil engineering. From excavations to pipeline constructions, well point dewatering broadly covers places.

Let’s understand how well point dewatering systems are used in different types of applications and how they can be beneficial for multiple purposes.

Read Also – What is dewatering in construction?

Applications:

- Excavation Projects:

The main goal of all such projects is to balance or remove the groundwater and maintain a dry environment. Well point dewatering can make your task easier, especially when your project requires digging for basements, underground parking, or building foundations.

- Construction Projects:

For the construction of tunnels, sewers, and pipelines, it is important to keep the groundwater under control and to avoid overflows and soil collapse.

- Foundation Work:

Building foundations needs to be done without any risk. Well point dewatering ensures a dry environment for areas prone to high groundwater levels.

- Road and Bridge Construction:

Road and bridge construction are big responsibilities. Hence, to ensure life security, dewatering is essential for safe soil conditions.

- Shallow Excavations:

Well point dewatering is also used for trenches, utility lines, and small excavation projects.

Benefits:

- Cost-Effective:

One of the most beneficial parts of choosing a well point dewatering pump is that they are relatively cost-effective compared to other dewatering options, especially for shallow depth projects.

- Minimal Disturbance:

The process of well point dewatering creates minimal disturbance and can be done with hardly any inconvenience. Well point dewatering is ideal for places with limited spaces, like urban cities and other congested areas.

- Efficiency:

During the excavation process, dewatering efficiently maintains a dry environment and ensures smooth functioning for your project.

- Flexibility:

Well point dewatering systems can be used in sandy soils with moderate permeability; they are easy to transport and install as well. Hence, providing flexibility and transparency.

- Environmentally Friendly:

Dewatering reduces the risk of overflows, flooding, and soil collapses. Therefore, it is necessary to dewater the site before starting your project to keep the surroundings safe.

Limitations and Challenges

Construction is no trivial matter. While solving many major issues, well point dewatering can have its own limitations and challenges. Challenges like depth limitations, soil type dependency, and environmental concerns are generally seen.

Let’s understand some commonly faced limitations and challenges during the process of well point dewatering.

- Limited Depth:

Well point dewatering is mainly used for shallow depths up to 5 – 6 meters. For lower excavations, well point dewatering systems require multiple stages.

- Soil Type Sensitivity:

Though well point dewatering works well in sandy or granular soils, it can be too slow for clayey or highly silty soils due to low water flow rates.

- Maintenance and Monitoring:

Well point dewatering requires regular maintenance and constant inspection of pumps, filters, and header systems. It is important to avoid air leaks, clogging, or failures.

- Environmental Impact:

In some cases, there can be a possibility of erosion, flooding, or contamination of natural bodies present in nearby areas.

Why Well Point Dewatering is a Preferred Choice in Construction

Before choosing any type of dewatering solution, it is necessary to determine your project’s size, soil type, site condition, and groundwater level. Whereas a well point dewatering solution is best for shallow and medium-depth excavations, they are cost-effective, flexible, and creates minimal disturbance as well.

Now, you know all about What is a Well Point Dewatering System & How it works? Are you still curious if the well point dewatering system fits your project?

Get all the answers with Raajgad Pumps, from equipment supply to technical expertise – we’ve got you covered.

Whether it is a short-term project or a long-term investment, we provide all products and rental services in Pune. For more information regarding dewatering systems, visit https://www.raajgadpump.com/dewatering-rental-services-in-pune/

FAQs

What is a well point dewatering system?

A well point dewatering system is a process of removing groundwater from a particular area.

How does a well point dewatering system work?

The procedure involves shallow wells, being connected to multiple pipes, and a suction pump that pulls out water from the ground.

What are the main components of a well point dewatering system?

A well point dewatering system comprises multiple necessary components like well points, header pipe, pump, and various other accessories.

What types of soils and excavations are suitable for well point dewatering?

Well point dewatering is an ideal choice for shallow excavations. And sandy and silty soils work best for them.

What is the typical depth range for well point dewatering?

5 to 7 meters, i.e, 16 – 23 feet per stage, is the typical depth range for well point dewatering.

How is a well point system installed?

Installing a well point dewatering system is quick and easy, but requires a systematic process of site preparation, positioning, jetting, and a stable pump network.

What are the advantages of using a well point dewatering system over other dewatering methods?

Well point dewatering is relatively cost-effective, easy to install, and flexible compared to other dewatering methods.